Consumables for Infusion

Advantages of using Compoflex®

- Superior peeling properties

- Controlled flow front

- Easy release minimises resin dust

- Time and cost savings

- Flow mesh

- Secondary bonding surface

Standard Compoflex®

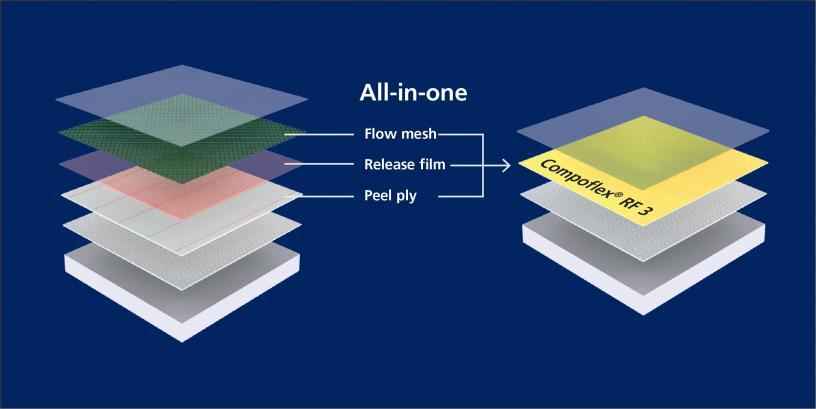

Compoflex® products are breathable micro-porous peeling materials, which replace up to three consumables – peel ply, release film and flow mesh – with a single layer in composite manufacturing.

Compoflex® offers benefits which include:

- Superior peeling properties

The micro-porous surface and the low surface tension of polypropylene (PP) nonwovens ensure that Compoflex® peels at one fifth of the force needed to peel conventional peel ply.

- Uniform bleeding

The random micro-porous perforation style enables uniform bleeding, ensuring stronger and lighter laminates. Overlapping is possible, without compromising laminate quality.

- Time and cost savings

In vacuum bagging, Compoflex® can replace three consumables – peel ply, release film and breather. Fewer consumables, combined with easy peeling, reduce costs and handling time, simplifying the process.

- Easy peeling minimises resin dust

Compoflex® peels easily and hardened resin remains in the liner, reducing the amount of airborne resin dust. Conventional peel ply generates intensive resin dust activity, causing an unhealthy working environment.

Process

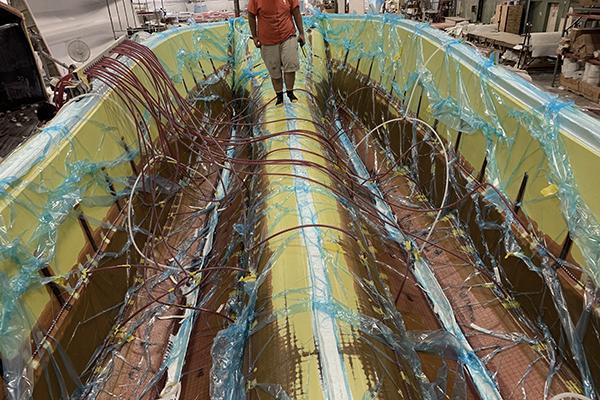

Resin Flow Compoflex® RF

- Time and cost savings

In the infusion process, Compoflex® RF replaces peel ply and flow mesh. Fewer consumables, combined with easy release, reduce costs and handling time, simplifying the process. Compoflex® RF is easy to lay, due to the integrated flexible grid.

Secondary Bonding Compoflex® SB

Compoflex® SB, with secondary bonding properties, is designed to produce a surface ready for secondary bonding, while maintaining the superior peeling properties of standard Compoflex® products.

Compoflex® SB products, which are offered in two versions for pre-preg and hand lay-up, may reduce or eliminate the need for sanding or abrading. Best results are achieved with epoxy resin, but testing is always recommended prior to application.

Secondary Bonding + Resin Flow Compoflex® SB RF

Compoflex® RF is also available in an SB RF version - with excellent combined surface advantages offered by secondary bonding and resin flow, to create a surface ready for bonding.

Compoflex® SB products may reduce or eliminate the need for sampling or abrading. Best results are achieved with epoxy resin, but testing is always recommended.

Due to the micro-porous surface of Compoflex®, bigger valves may be required, depending on laminate size and thickness.

Related cases

Related products

Compoflex® 150

Compoflex® 150 is a peel ply and release film, used to control flow rate and release consumables from a composite laminate.

Compoflex® SB 150

Compoflex® SB 150 is a peel ply and release film, used to control flow rate and release consumable from a composite laminate.

Compoflex® RF 3

Compoflex® RF 3 is a peel ply, release film and flow mesh, used to control flow rate, distribute resin and release consumables from a composite laminate.

Compoflex® SB RF 3

Compoflex® SB RF 3 is a peel ply, release film and flow mesh, used to control flow rate, distribute resin and release consumables from a composite laminate.

Contact

Find contact person

Find a relevant contact person within the composites business area.