Composites

Innovating composites processes

Fibertex’ solutions for composites are used to build some of the longest blades for wind turbines, luxury boats, the fastest cars, trains, planes, and much more.

The applications vary greatly and so do the core benefits. They include cost-effective solutions, easy handling, peeling etc. Our focus is on manufacturing lighter, stronger, high-performance composite products in addition to highly efficient processing.

As an experienced partner, we help our customers reach new levels of product development, we help them discover new ways of solving old problems, and we serve as a strong partner to help realise ideas.

How we add value to your business

- Save valuable production time and cost with easy handling

- Benefit from easy lay-up, superior peeling and bonding properties, uniform bleeding and more

- Reach new levels of innovation together

What are composites

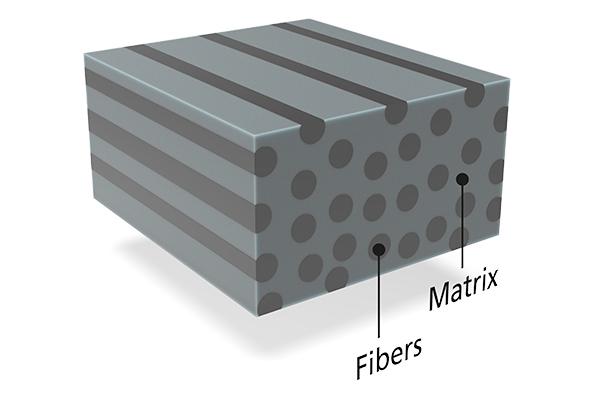

Fibre-reinforced plastic (FRP) is a composite material made of a polymer matrix reinforced with fibres.

The fibres are usually glass (in fibreglass), carbon (in carbon fibre reinforced polymer), aramid, or basalt.

The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic.

The product in use

Fibertex high-performance composite materials are used to build some of the longest blades for wind turbines and also offer the finest solutions for luxury boats, the fastest cars, high-speed trains and airplanes.

Typical process technologies are infusion and vacuum moulding. There is no limit to the possibilities for these composite materials.

Products

COMPOFLEX® VIDEO GALLERY

Visit Fibertex Composites Video Gallery to learn more about how Compoflex® is utilized in the production process of composite products.

Composites Cases

Examples of applications

We have listed a selection of Composites applications where nonwovens are used.

Luxury boats

Race cars

Blades for wind turbines

Glass reinforced bridges

Glass reinforced pipes

Cars

Contact

Find Contact Person

Find a relevant contact person within the composites business area by choosing your region or country.