FiberRails ST

Railways are supported by ballast to ensure maximum friction. Unfortunately, over time this friction will be seriously reduced by the vibration caused by recurring traffic.

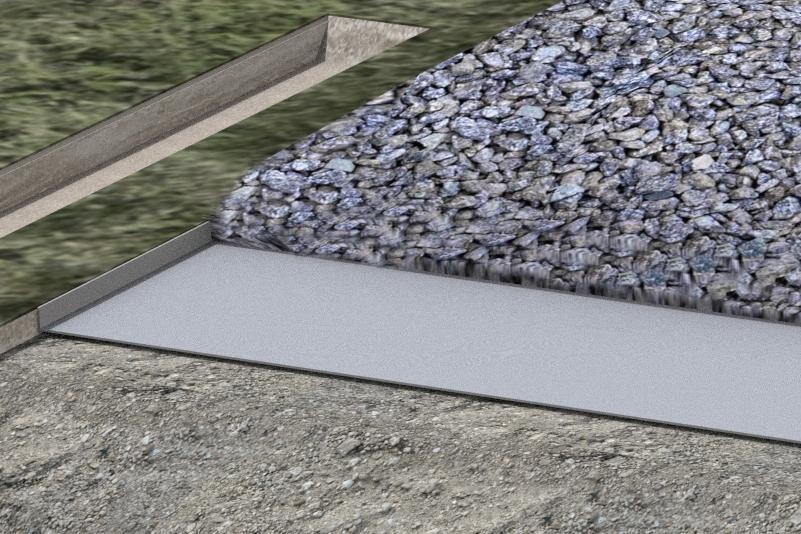

You can overcome this challenge by applying FiberRails ST to the bearing surface before laying the new ballast as it provides effective separation and filtration resulting in improved bearing capacity and service lifetime of the track. Additionally, dampening vibration also reduces noise levels, which is important, especially in urban areas.

With FiberRails ST, you will be able to improve service life and stop the critical pumping effect, helping you to:

- Ensure a reliable timetable

- Improve railway maintenance and lifetime

- Reduce noise levels due to dampened vibration

The abrasion resistance of FiberRails ST is required and certified especially for this application by the French train operator SNCF.

Contact

Find Contact Person

Find your local contact person for questions regarding specific applications by choosing your region or country.