Compoflex®

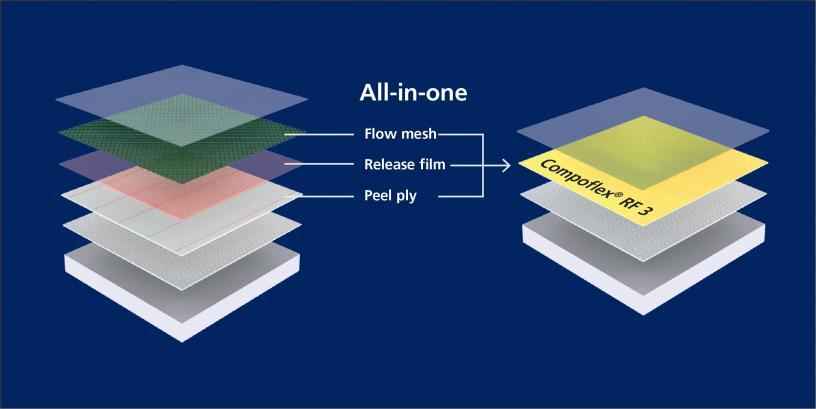

Fibertex Compoflex® products are breathable micro-porous peeling materials, designed to replace up to three consumables – peel ply, release film and breather – with a single layer in composite manufacturing.

Compoflex® for infusion

In the resin infusion process, dry fibre material is placed directly in the mould. A distribution fabric or grid is installed to ensure correct resin flow and optimal vacuum distribution. A peel-ply is installed as a separator between the dry fibre material and the distribution fabric. Compoflex® 150 replaces the peel-ply and ensures easy peeling, leaving a clean surface.

Compoflex® for vacuum moulding

In the vacuum bagging process, the lay-up consists of a laminate, peel-ply, release film and a breather/bleeder fabric. Compoflex® can replace all of these products, simplifying the process.

Compoflex® Products

Product | Material | Weight | Release coating | Colour | Process | Function |

|---|---|---|---|---|---|---|

PP | 150 gsm | None/easy release | White | Infusion | Release fabric Release film | |

PP | 150 gsm | None/easy release | White | Infusion | Release fabric Release film Surface for Secondary bonding | |

| Compoflex® RF 3 | PP/HDPE | 335 gsm | None/easy release | White/Yellow | Infusion | Release fabric Release film High speed flow mesh |

PP/HDPE | 335 gsm | None/easy release | White/Yellow | Infusion | Release fabric Release film High speed flow mesh Surface for Secondary bonding | |

| Compoflex® 250 | PP | 250 gsm | None/easy release | White | Pre-preg | Release fabric Release film 150g breather (5 oz) |

| Compoflex® SB 250 | PP | 250 gsm | None/easy release | White | Pre-preg Wet lay up | Release fabric Release film 150g breather (5 oz) Surface for Secondary bonding |

PP | 400 gsm | None/easy release | White | Pre-preg | Release fabric Release film 300g breather (10 oz) | |

PP | 400 gsm | None/easy release | White | Pre-preg | Release fabric Release film 300g breather (10 oz) Surface for Secondary bonding |

Maximum use temperature

The melting point for polypropylene is 165°C (329°F) and our recommended working temperature is approx. 145°C (293°F). However, we do have customers using Compoflex at 200°C (392°F). This is because Compoflex performs before the temperature exceeds the melting point. Peeling is just as easy and the material becomes stable again. We recommend conducting a test on a small part first.

Features and installation of Compoflex®

- Easy lay-up with only one product.

- Always place the smooth side against the laminate.

- Always place the fluffy side against the vacuum bag.

- We recommend testing on a small part, prior to full scale installation.

- This material can be pre-cut with a CNC or hand cut with scissors.

- Overlap is possible.

- This material works well with polyester, vinylester, epoxy, phenolic and other types of resin.

- The melting point for polypropylene is 165°C (329°F) Recommended working temperature is approx. 145°C (293°F). Maximum temperature, depending on process, is 200°C (392°F).

Applications

Consumables for Infusion

Consumables for Vacuum Moulding

Composites Cases

Contact

Find Contact Person

Find a relevant contact person within the composites business area by choosing your region or country.

Relevant Brochures

Video Gallery

In our video gallery you can find videos of:

- Compoflex® RF 3 - Sea Ray

- Full scale test at MAGBOAT

- Peeling comparison